Index

Production of plastic powder feedstocks for additive manufacturing by precipitation

Funded by Deutsche Forschungsgemeinschaft (DFG) – Project number 409808524

Funded by Deutsche Forschungsgemeinschaft (DFG) – Project number 409808524

The overall aim of this project within priority program 2122 “Materials for Additive Manufacturing” is the development of novel semi-crystalline polymer powders for selective laser sintering (SLS) via a liquid-liquid phase separation (LLPS) and subsequent crystallization for polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyoxymethylene (POM) and polyvinylidene fluoride (PVDF). Selection criteria for appropriate solvents for LLPS will be deduced by an iterative screening method based on Hildebrand and Hansen solubility parameters. In-situ model LLPS experiments employing dynamic light scattering, optical microscopy and impedance spectroscopy –supported by ex-situ electron microscopy- will allow for deeper insights into the phase separation and particle formation mechanisms. A detailed mechanistic understanding of the underlying mechanism of LLPS, i.e. nucleation, droplet coalescence and growth and elucidation of their dependencies on system composition, time-temperature history will be achieved. LLPS will be implemented on the mini plant scale, where the effect of process parameters (e.g. influence of stirring, cooling regime) on material and bulk solid properties of the obtained polymer particles will be systematically studied. Moreover, in-situ functionalization of the particles with nanoparticulate flowing aids and additive enhancement with thermal stabilizers (antioxidants) will be studied, scale-up criteria will be deduced and powder amounts applicable for studies on SLS processing behavior (several 100 grams to the kilogram scale) will be produced. A detailed structural characterization of the obtained SLS particles with respect to crystallinity, polymorphism, thermal characteristics and morphology will be performed employing amongst others dynamic scanning calorimetry, X-ray diffraction, vibrational spectroscopy (IR, Raman) and electron microscopy. The effect of process parameters on molar mass distributions of the polymer and melt viscosity will be assessed by gel permeation chromatography and melt rheology. Bulk solid characteristics such as the product particle size distribution and the powder flowability which are seen to be most important for processing will be characterized by laser diffraction particle sizing, respectively shear testers and powder application model experiments. The gained understanding of the structure-property relationships and the information on SLS processability provided by the cooperation partners will be utilized for further LLPS process optimization to tailor the desired properties of the novel SLS powders. Novel SLS powders with improved material behavior, i.e. chemical resistance (PET, PBT, PVDF), impact resistance (PBT), high stiffness, excellent dimensional stability (PET, PBT, POM) shall be developed widening the field of application of SLS-manufactured parts.

Publications:

- , , , , , :

Poly(butylene terephthalate) for Laser Powder Bed Fusion of Polymers: Feedstock Precipitation and Powder Characterization

In: ACS Applied Polymer Materials (2024)

ISSN: 2637-6105

DOI: 10.1021/acsapm.4c01573 - , :

Dry powder coating in additive manufacturing

In: Frontiers of Chemical Science and Engineering 4 (2022)

ISSN: 2095-0179

DOI: 10.3389/fceng.2022.995221 - , , , , , , :

A novel, precipitated polybutylene terephthalate feedstock material for powder bed fusion of polymers (PBF): Material development and initial PBF processability

In: Materials & Design 197 (2021), Article No.: 109265

ISSN: 0264-1275

DOI: 10.1016/j.matdes.2020.109265 - , :

Flüssig-Flüssig-Phasentrennung und Fällung zur Herstellung neuartiger Ausgangsmaterialien für das pulverbettbasierte Schmelzen von Polymeren

17th Rapid.Tech 3D Conference (Erfurt, 22. June 2021 - 23. June 2021)

In: Proceedings of the 17th Rapid.Tech 3D Conference Erfurt, Germany, 22–23 June 2021 2021

DOI: 10.3139/9783446471733.001 - , , , , , , , , :

Quality over quantity: How different dispersion qualities of minute amounts of nano-additives affect material properties in powder bed fusion of polyamide 12

In: Materials 14 (2021), Article No.: 5322

ISSN: 1996-1944

DOI: 10.3390/ma14185322 - , , :

Development of polyoxymethylene particles via the solution-dissolution process and application to the powder bed fusion of polymers

In: Materials 13 (2020), Article No.: 1535

ISSN: 1996-1944

DOI: 10.3390/ma13071535 - , :

On the development of polymer particles for laser powder bed fusion via precipitation

In: Procedia CIRP 94 (2020), p. 95-99

ISSN: 2212-8271

DOI: 10.1016/j.procir.2020.09.019 - , , , , , , , , , :

3D printing of magnetic parts by laser powder bed fusion of iron oxide nanoparticle functionalized polyamide powders

In: Journal of Materials Chemistry C 8 (2020), p. 12204-12217

ISSN: 2050-7526

DOI: 10.1039/d0tc02740e

Formulation of dispersed systems via melt emulsification

Funded by Deutsche Forschungsgemeinschaft (DFG) – Project number 504809428

Funded by Deutsche Forschungsgemeinschaft (DFG) – Project number 504809428

The aim of this project within priority program 2364 “Autonomous processes in particle technology” is the automated production of liquid-liquid disperse systems via melt emulsification, whereby in this process emulsification takes place at elevated temperature. The products obtained after cooling are dispersions of spherical nanoparticles or microparticles. Within the scope of this project, a melt emulsification device for the automated production of product particles with a well-defined particle size distribution (PSD) will be further developed. The PSD has a significant influence on the subsequent product properties, such as flow behavior or drug release kinetics. The PSD of the products is determined by the complex interaction of competing mechanisms. These are, in particular, droplet breakup in a rotor-stator device as a result of shear and elongation stress, as well as coalescence and further ripening, which in turn depend on the system composition, i.e. the emulsifier used (type, concentration) and the dispersion phase (viscosity, volume fraction). Therefore, for a better process understanding and an active process control, possibilities for in situ determination of the PSD are urgently required. In this project, a novel fiber-coupled measurement system based on broadband elastic light scattering is developed for in situ measurement of the PSD. The system will be validated on reference particle systems and applied to the emulsification process. Furthermore, a hybrid process model is developed, which is the basis for the design of a model predictive control of the process. The model predictive control in combination with the in situ measurement will provide the possibility for an active process control and the production of emulsions with predefined properties and a simultaneous optimization of the process time.

Publications:

- , , , :

GP-based modeling for PSD control of emulsification processes

28th International Conference on System Theory, Control and Computing (ICSTCC) (Sinaia, Romania, 10. October 2024 - 12. October 2024)

Formulation of hetero-aggregates

Funded by Deutsche Forschungsgemeinschaft (DFG) – Project number 46231449

Funded by Deutsche Forschungsgemeinschaft (DFG) – Project number 46231449

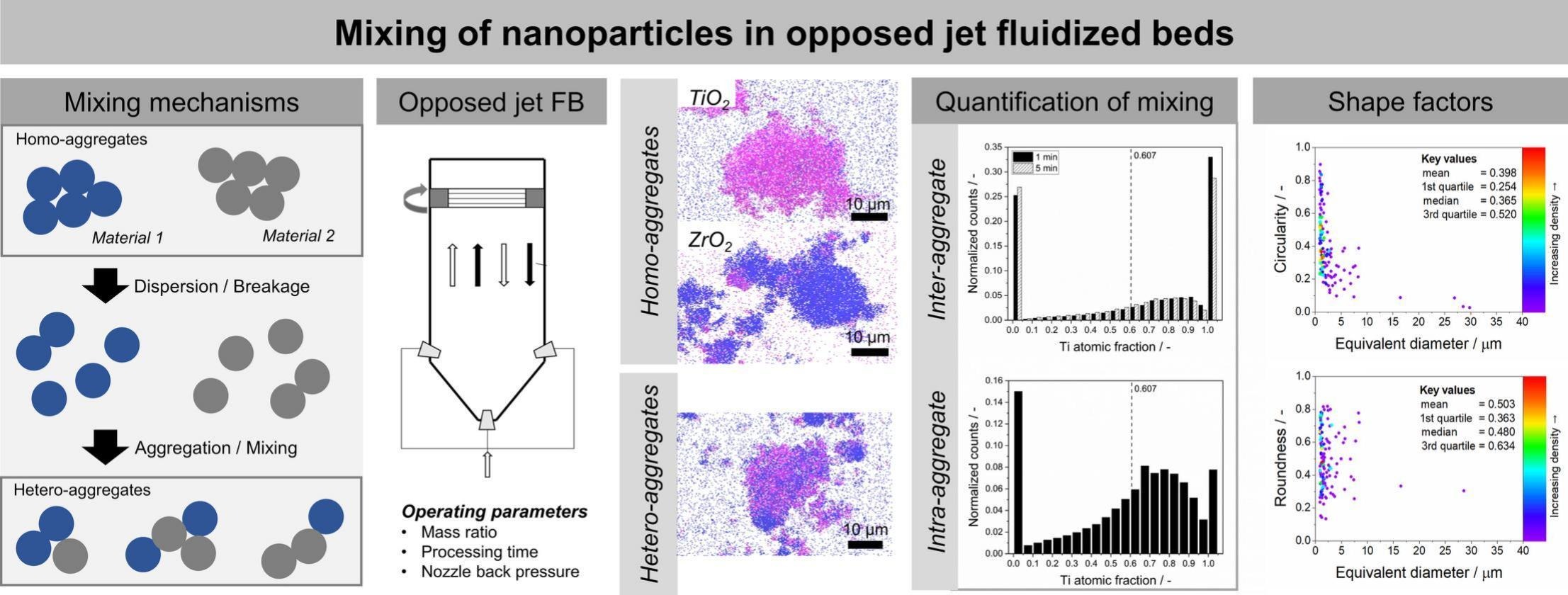

The vision of the project within priority program 2289 “Hetero-Aggregates” is the establishment of a continuous process for formulation of ternary hetero-aggregates from dry primary particles. The functionality of the hetero-aggregates is grounded in the designed composition and distribution of hetero-contacts between constituents achieved by mixing at the primary particle scale (~ 25 nm). Process modelling is an integral part of the project: Firstly, to establish the process function of the formulation process (in the Rumpfian sense). Secondly, to generate tools for model-based sensor fusion, process optimization and control. Comprehensive characterization of hetero-aggregate properties links experiments and the simulation studies, iteratively providing validation and improvement of process models and experimental design as well as revealing the material functions of hetero-aggregate formulation in opposed jet fluidized beds. Having established the processing strategy, characterization methods, fundamental models of mixing of binary nanoscale primary particles into aggregates, and the connection between process parameters and structural parameters of the aggregates, the second funding period will see a continuation and extension of the focus towards functionality of the hetero-aggregates. The main designed functionality of the hetero-aggregates is photocatalytic activity by designing hetero-aggregate structures consisting of TiO2 and ZrO2 primary particles via composition and formation of hetero-junctions. Furthermore, a third component, bismuth vanadate, BiVO4, will be added to form ternary hetero-aggregates, extending the accessible range of the electromagnetic spectrum for “harvesting” electrons required in photocatalysis and to increase the efficiency of the separation of the generated electron-hole pairs, thus allowing design of an improved photocatalyst. The objectives of the project are: i) Establishment of a continuous ternary hetero-aggregate formulation process in opposed jet fluidized beds; elucidation of structure formation towards design functionality; ii) Development of a CFD-informed multivariate population balance model for formulation ternary hetero-aggregates; iii) Development of a model-based soft-sensor for photocatalytic activity of the hetero-aggregates, taking into account property and structure distributions (e.g., size, composition); iv) Model-based analysis, optimization and control of formation dynamics, structural properties and functionality by population balance models and soft-sensor; v) Extension of the SEM-EDX and the Raman mapping approach to characterize the intra- and inter-aggregate composition and mixing of ternary hetero-aggregates; vi) Elucidation of the optical, electronic and photochemical properties of ternary hetero-aggregates formed from semiconductors and characterization of the heterojunction (bulk behavior); vii) Linking of hetero-aggregates properties on the single aggregate level with bulk behavior and photocatalytic performance.

Publications:

- , , , , :

Formulation of hetero-aggregates in opposed jet fluidized beds

In: Powder Technology 461 (2025), Article No.: 121099

ISSN: 0032-5910

DOI: 10.1016/j.powtec.2025.121099 - , , , , , , :

Formulation of Nanostructured Heteroaggregates by Fluidization Technologies

In: Chemie Ingenieur Technik (2022)

ISSN: 0009-286X

DOI: 10.1002/cite.202200139

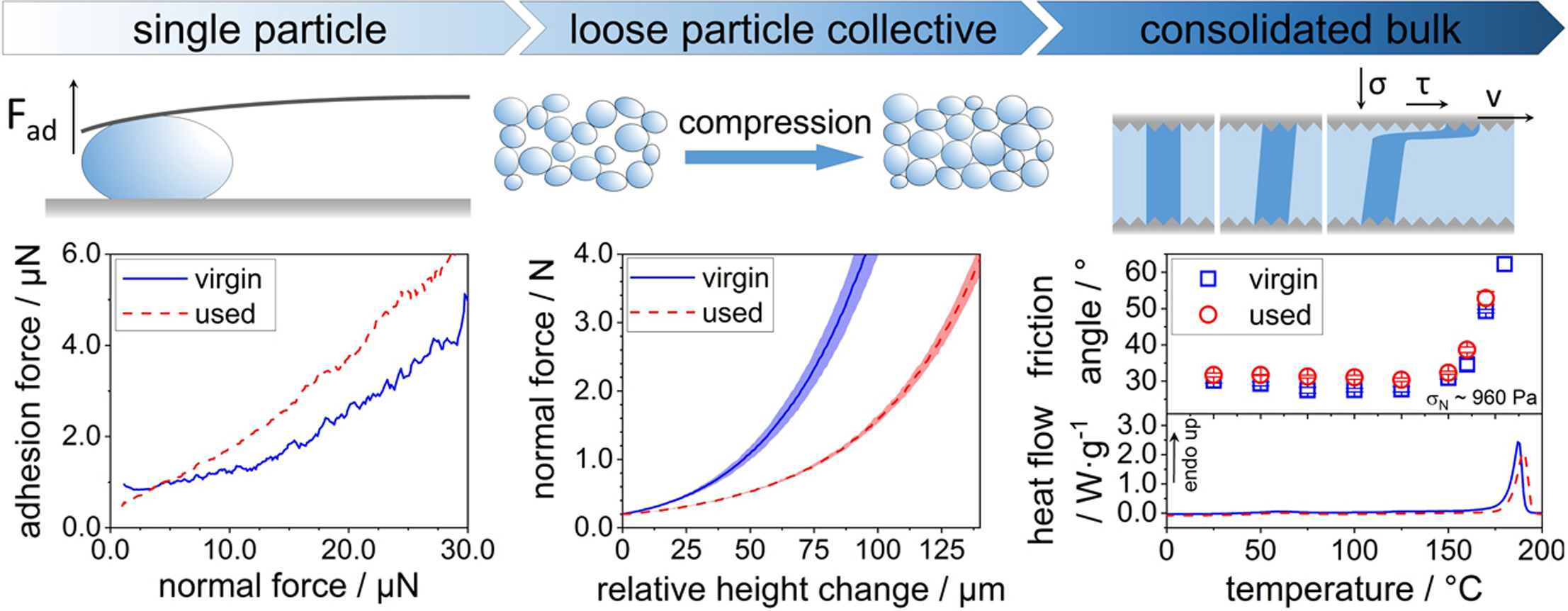

Quality assurance system for polymer powders used in additive manufacturing

Funded by Deutsche Forschungsgemeinschaft (DFG) – Project number 61375930

Funded by Deutsche Forschungsgemeinschaft (DFG) – Project number 61375930

Aim of this transfer project of CRC 814 “Additive Manufacturing” is the scientific development of a quality assurance system for polymer powders used in laser beam melting. The quality assurance system is based on two methods. First, an empirical model for ageing of polymers will be established, which considers beside chemical additionally physical ageing mechanism. The model is based on experimentally determined bulk material properties as well as rheological and thermal properties of the present material system. The material model in combination with process data allows the prediction of the ageing state and will lead to a demonstrator software, which will be experimentally validated. Furthermore, a measuring system will be developed, which allows for determination of powder flowability at elevated temperatures and rheological properties of the polymer melt. After validation, the quality assurance system will be transferred to a demonstrator system in close cooperation with the industry partner.

Publications:

- , , , , , , :

From trash to treasure in additive manufacturing: Recycling of polymer powders by acid catalyzed hydrolysis

In: Additive Manufacturing 71 (2023), Article No.: 103591

ISSN: 2214-7810

DOI: 10.1016/j.addma.2023.103591 - , , , :

Towards a generally applicable methodology for the characterization of particle properties relevant to processing in powder bed fusion of polymers – from single particle to bulk solid behavior

In: Additive Manufacturing (2021), p. 101957

ISSN: 2214-7810

DOI: 10.1016/j.addma.2021.101957 - , , , :

Selektives Laserstrahlschmelzen von Polyamid 12 - Einfluss von Fließhilfsmitteln auf Verarbeitbarkeit und Bauteileigenschaften

Rapid.Tech 2021 (, 22. June 2021 - 23. June 2021)

In: Proceedings of the 17th Rapid.Tech Conference 2021

DOI: 10.3139/9783446471733.002 - , , :

Enhancement of polyamide laser sinter powder reusability by acid catalyzed hydrolysis

In: Procedia CIRP 94 (2020), p. 105-109

ISSN: 2212-8271

DOI: 10.1016/j.procir.2020.09.021

Functional polymer particles via liquid-based top-down processes

Funded by Deutsche Forschungsgemeinschaft (DFG) – Project number 6137593

Funded by Deutsche Forschungsgemeinschaft (DFG) – Project number 6137593

Aim of this sub-project of CRC 814 “Additive Manufacturing” is process intensification and optimization of process parameters in view of minimization of alteration of intrinsic polymer properties due to processing. A continuous wet grinding – separation circuit will allow for an increased yield of the target particle size fraction and optimal control of particle residence time. The melt emulsification approach, amongst others, will be performed for low-viscous polymer waxes. The obtained particles will be subjected to solid state polymerization. Precipitation will be utilized for production of microparticle filled systems.

Publications:

- , , , , :

Thermo‐Optical Analysis of Surface‐ and Volume‐Additivated Polymer Powders for Near‐Infrared Laser Powder Bed Fusion

In: Advanced Photonics Research (2025), Article No.: 2400207

ISSN: 2699-9293

DOI: 10.1002/adpr.202400207 - , , , , , , , , , :

Magnetic polyamide 11 powder for the powder bed fusion process by liquid-liquid phase separation and crystallization

In: Additive Manufacturing 88 (2024), Article No.: 104250

ISSN: 2214-7810

DOI: 10.1016/j.addma.2024.104250 - , , , , , :

Poly(butylene terephthalate) for Laser Powder Bed Fusion of Polymers: Feedstock Precipitation and Powder Characterization

In: ACS Applied Polymer Materials (2024)

ISSN: 2637-6105

DOI: 10.1021/acsapm.4c01573 - , , , , , :

Polyamide 11 nanocomposite feedstocks for powder bed fusion via liquid-liquid phase separation and crystallization

In: Powder Technology 424 (2023), Article No.: 118563

ISSN: 0032-5910

DOI: 10.1016/j.powtec.2023.118563 - , :

Dry powder coating in additive manufacturing

In: Frontiers of Chemical Science and Engineering 4 (2022)

ISSN: 2095-0179

DOI: 10.3389/fceng.2022.995221 - , , , , , :

Abrasion-Induced Acceleration of Melt Crystallisation of Wet Comminuted Polybutylene Terephthalate (PBT)

In: Polymers 14 (2022), p. 810

ISSN: 2073-4360

DOI: 10.3390/polym14040810 - , , , :

Production of spherical ester wax powders by melt emulsification for Additive Manufacturing

12th CIRP Conference on Photonic Technologies, LANE 2022 (Erlangen, 4. September 2022 - 8. September 2022)

In: M. Schmidt, F. Vollertsen, B.M. Colosimo (ed.): Procedia CIRP 2022

DOI: 10.1016/j.procir.2022.08.110 - , , , , :

Semi‐Crystalline Polyetherimide Microparticles via Liquid‐Liquid Phase Separation and Precipitation

In: Macromolecular Materials and Engineering (2022), p. 2100797

ISSN: 1438-7492

DOI: 10.1002/mame.202100797 - , , , , :

Infiltration behavior of liquid thermosets in thermoplastic powders for additive manufacturing of polymer composite parts in a combined powder bed fusion process

In: Polymer Composites (2021)

DOI: 10.1002/pc.26221 - , , , , , , , , :

Development of poly(L-lactide) (PLLA) microspheres precipitated from triacetin for application in powder bed fusion of polymers

In: Additive Manufacturing 32 (2020), Article No.: 100966

ISSN: 2214-7810

DOI: 10.1016/j.addma.2019.100966 - , , , , :

Production of PBT/PC multi-material particles via a combination of co-grinding and spray-agglomeration for powder bed fusion

In: Procedia CIRP 94 (2020), p. 100-104

ISSN: 2212-8271

DOI: 10.1016/j.procir.2020.09.020 - , , , , , , :

Packings of micron-sized spherical particles – Insights from bulk density determination, X-ray microtomography and discrete element simulations

In: Advanced Powder Technology (2020)

ISSN: 0921-8831

DOI: 10.1016/j.apt.2020.03.018 - , , , , , , , , , :

Production of polyamide 11 microparticles for Additive Manufacturing by liquid-liquid phase separation and precipitation

In: Chemical Engineering Science 197 (2019), p. 11-25

ISSN: 0009-2509

DOI: 10.1016/j.ces.2018.11.051 - , , , :

Formation of spherical micron-sized polyamide particles for additive manufacturing via liquid-liquid phase separation

33rd International Conference of the Polymer Processing Society, PPS 2017 (Cancun, MEX, 10. December 2017 - 14. December 2017)

In: Octavio Manero, Fausto Calderas (ed.): AIP Conference Proceedings 2019

DOI: 10.1063/1.5121696 - , , , :

Production of Spherical Micron-Sized Polymer Particles for Additive Manufacturing by Liquid Phase Processes

Europe/Africa Regional Dresden Conference of the Polymer-Processing-Society (PPS) (Dresden, 27. June 2017 - 29. June 2017)

In: Proceedings of the Europe/Africa Conference Dresden 2017 Polymer Processing Society PPS, MELVILLE: 2019

DOI: 10.1063/1.5084905 - , , , , , , :

Manufacturing and Application of PA11-Glass Fiber Composite Particles for Selective Laser Sintering

30th Annual International Solid Freeform Fabrication Symposium 2019 (Austin, TX)

In: Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium 2019 2019

URL: http://utw10945.utweb.utexas.edu/sites/default/files/2019/089 Manufacturing and Application of PA11-Glass Fiber.pdf - , , , , , , :

Manufacturing of nanoparticle-filled PA11 composite particles for selective laser sintering

30th Annual International Solid Freeform Fabrication Symposium 2019 (Austin, TX)

In: Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium 2019 2019

Open Access: http://utw10945.utweb.utexas.edu/sites/default/files/2019/090 Manufacturing of Nanoparticle-Filled PA11 Composit.pdf - , , , , :

Process Routes towards Novel Polybutylene Terephthalate – Polycarbonate Blend Powders for Selective Laser Sintering

30th Annual International Solid Freeform Fabrication Symposium 2019 (Austin, TX)

In: Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium 2019 2019

Open Access: http://utw10945.utweb.utexas.edu/sites/default/files/2019/068 Process Routes towards Novel Polybutylene Terephth.pdf

URL: http://utw10945.utweb.utexas.edu/sites/default/files/2019/068 Process Routes towards Novel Polybutylene Terephth.pdf - , , , , , :

Characterization of Polymer Powders for Selective Laser Sintering

30th Annual International Solid Freeform Fabrication Symposium 2019 (Austin, TX)

In: Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium 2019 2019

Open Access: http://utw10945.utweb.utexas.edu/sites/default/files/2019/066 Characterization of Polymer Powders for Selective.pdf

URL: http://utw10945.utweb.utexas.edu/sites/default/files/2019/066 Characterization of Polymer Powders for Selective.pdf - , , , , , :

Novel process routes towards the production of spherical polymer powders for selective laser sintering

33rd International Conference of the Polymer Processing Society, PPS 2017 (Cancun, MEX, 10. December 2017 - 14. December 2017)

In: Octavio Manero, Fausto Calderas (ed.): AIP Conference Proceedings 2019

DOI: 10.1063/1.5121697 - , , , :

Production of spherical semi-crystalline polycarbonate microparticles for Additive Manufacturing by liquid-liquid phase separation

In: Powder Technology 335 (2018), p. 275-284

ISSN: 0032-5910

DOI: 10.1016/j.powtec.2018.05.005 - , , , , , , :

Spherical Polybutylene Terephtalate (PBT)-Polycarbonate (PC) Blend Particles by Mechanical Alloying and Thermal Rounding

In: Polymers 10 (2018), Article No.: 1373

ISSN: 2073-4360

DOI: 10.3390/polym10121373 - , , :

Production of PBT/PC particle systems by wet grinding

32nd International Conference of the Polymer Processing Society, PPS 2016

DOI: 10.1063/1.5016720 - , , , , :

New approaches towards production of polymer powders for selective laser beam melting of polymers

32nd International Conference of the Polymer Processing Society, PPS 2016

DOI: 10.1063/1.5016797 - , , , , :

Production of spherical wax and polyolefin microparticles by melt emulsification for additive manufacturing

In: Chemical Engineering Science 141 (2016), p. 282-292

ISSN: 0009-2509

DOI: 10.1016/j.ces.2015.11.019

URL: http://www.sciencedirect.com/science/article/pii/S0009250915007368 - , , , :

Production of micron-sized polymer particles for additive manufacturing by melt emulsification

31st International Conference of the Polymer Processing Society, PPS 2015 (Jeju Island Korea, 7. June 2015 - 11. June 2015)

In: AIP Publishing LLC. (ed.): Proceedings of PPS-31 2016

DOI: 10.1063/1.4942342 - , , , , , , , :

Production of polybutylene terephtalate glass composite powders and characterization for processing in selective laser sintering

26th Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference (Austin, 8. August 2016 - 10. August 2016) - , , , , :

Herstellung und Funktionalisierung neuartiger Pulverwerkstoffe für die additive Fertigung

In: Chemie Ingenieur Technik 88 (2016)

ISSN: 0009-286X

DOI: 10.1002/cite.201650354 - , , , , :

Novel approaches for the production of polymer powders for selective laser beam melting of polymers

27th Annual International Solid Freeform Fabrication Symposium - An Additive Manufacturing Conference, SFF 2016 (Austin, Texas, 8. August 2016 - 10. August 2016)

In: Solid Freeform Fabrication 2016: Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference 2016

Open Access: https://www.sffsymposium.org/

URL: https://www.scopus.com/record/display.uri?eid=2-s2.0-85058166373&origin=inward - , , , , , , , :

Optimized polybutylene terephthalate powders for selective laser beam melting

In: Chemical Engineering Science 156 (2016), p. 1-10

ISSN: 0009-2509

DOI: 10.1016/j.ces.2016.09.009 - , , , , , , , , :

A novel process for production of spherical PBT powders and their processing behavior during laser beam melting

31st International Conference of the Polymer Processing Society, PPS 2015 (Jeju Island Korea, 7. June 2015 - 11. June 2015)

In: 31st International Conference of the POLYMER PROCESSING SOCIETY 2016

DOI: 10.1063/1.4942343 - , , , , , , :

A novel process chain for the production of spherical sls polymer powders with good flowability

7th World Congress on Particle Technology, WCPT 2014 (Bejing, 19. May 2014 - 22. May 2014)

In: Proceedings of the 7th World Congress on Particle Technology, WCPT 2014 2015

DOI: 10.1016/j.proeng.2015.01.123 - , , , , , , :

A novel process route for the production of spherical SLS polymer powders

30th International Conference of the Polymer Processing Society, PPS 2014 (Cleveland,Ohio, 6. June 2014 - 12. June 2014)

In: American Institute of physics (ed.): Proceedings of PPS-30 : the 30th International Conference of the Polymer Processing Society : conference papers : 6-12 June 2014, Cleveland, Ohio, USA 2015

DOI: 10.1063/1.4918518 - , , , , , , :

A novel process route for the production of spherical LBM polymer powders with small size and good flowability

In: Powder Technology 261 (2014), p. 78-86

ISSN: 0032-5910

DOI: 10.1016/j.powtec.2014.04.003 - , , , :

Production of polymer particles below 5 μm by wet grinding

In: Powder Technology 228 (2012), p. 84-90

ISSN: 0032-5910

DOI: 10.1016/j.powtec.2012.04.064